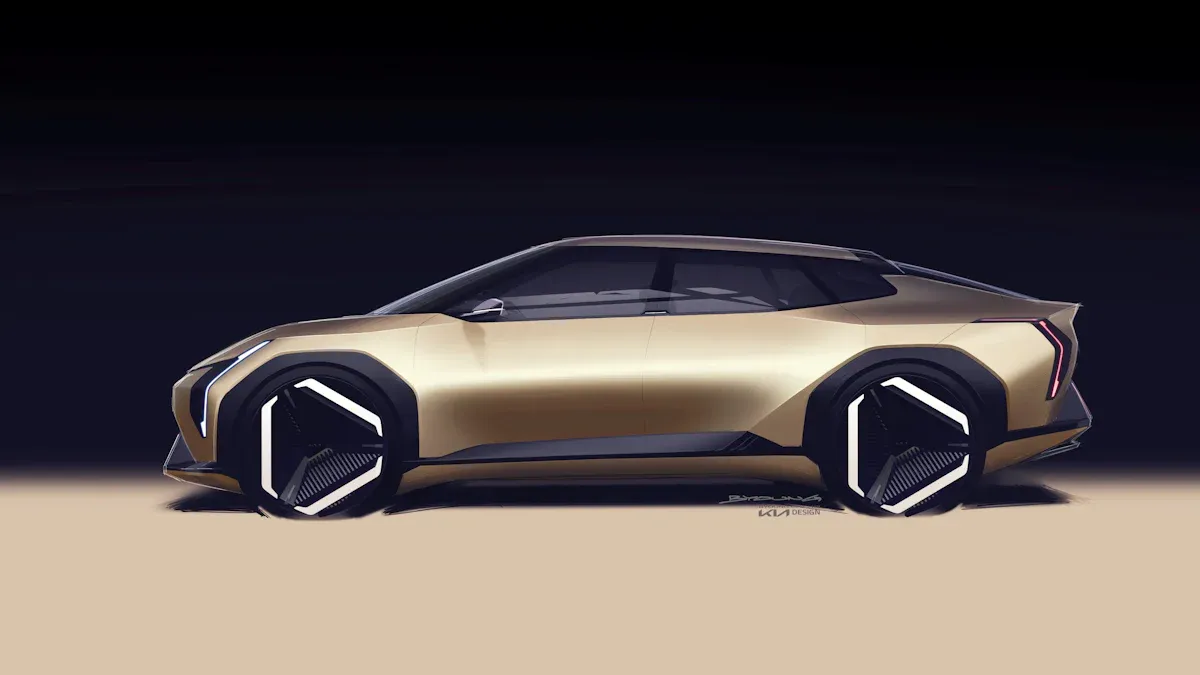

Aluminium extrusion profiles e fetola papali ea ho etsa likoloi. U rua molemo ka ho feto-fetoha ha moralo o ntlafalitsoeng, o lumellang hore ho be le mekhoa e mecha ea likoloi. Thepa e bobebe ea lintlha tsena e thusa ho fokotsa boima ba koloi ka kakaretso, e ntlafatsang ts'ebetso ea mafura le ho theola likhase. 'Maraka oa aluminium extrusion oa likoloi o ne o nkoa e le oa bohlokoa$ 76.58 bilione ka 2023'me e reretsoe ho fihla ho USD 147.08 limilione tse likete ka 2031. Khōlo ena e bontša phetoho e matla ho mekhoa e tsitsitseng le tlhokahalo e ntseng e eketseha ea likoloi tsa motlakase, tse itšetlehileng ka thepa e bobebe bakeng sa ts'ebetso e nepahetseng.

Lintlha tsa bohlokoa

- Profaele ea aluminium extrusion e fokotsa boima ba koloi, e ntlafatsa ts'ebetso ea mafura le ho theola mesi. Sena se ka lebisa ho phokotso ea boima ba lik'hilograma tse 35 koloing ka 'ngoe.

- Liprofaele tsena li ntlafatsa polokeho ea koloi ka ho monya matla a matla nakong ea ho thulana. Moralo oa bona o lumella deformation e ntle, e ntlafatsang ho senyeha.

- Aluminium extrusion profiles kee bolokang chelete ka nako e telele. Le hoja litšenyehelo tsa pele tsa lisebelisoa li ka 'na tsa e-ba holimo, hangata li baka litšenyehelo tse tlaase tsa tlhokomelo le ho tšoarella hamolemo.

- Ho sebelisa aluminiume tshehetsa moshoelellaindastering ea likoloi. E ka ba le ho fihla ho 75% ea lintho tse sebelisoang hape 'me aluminiamo ea ho sebelisa hape e sebelisa matla a tlase ho 95% ho feta ho hlahisa aluminium e ncha.

- Lifaele tsa aluminium li na le mekhoa e mengata ea moralo oa likoloi, li loketse likarolo tsa sebopeho, likarolo tsa botle, le litsamaiso tsa taolo ea mocheso, li ntlafatsa ts'ebetso le setaele.

Melemo ea Aluminium Extrusion Profiles

Thepa e bobebe

Aluminium extrusion profiles e fokotsa boima ba koloi haholo, e amang ts'ebetso le katleho ka kotloloho. Ka ho sebelisa liprofaele tsena, u ka fihlela phokotso ea boima ba 'mele ea hoo e ka bang35 liponto koloi ka 'ngoe. Phokotso ena e lebelletsoe ho eketseha hoo e batlang e le45 liponto koloi ka 'ngoeka 2025. Ho boloka boima bo joalo ho lebisa ho ntlafatseng ts'ebetso ea mafura le ho fokotsa mesi, ho etsa hore likoloi tsa hau li se ke tsa silafatsa tikoloho. Ha e le hantle, mekhatlo ea lisebelisoa tsa aluminium e ka fella ka hoPhokotso ea 35% ea boima ba 'melebapisoa le balekane ba setso tšepe. Monyetla ona o bobebe o bohlokoa kaha indasteri ea likoloi e fetohela mekhoeng e tšoarellang.

Matla a Matlafalitsoeng le Tšireletseho

U ka 'na ua makatsoa ke ho tseba hore profil ea aluminium extrusion ha e fane feela ka melemo e bobebe empa hape e fana ka matla le ho tšoarella nako e telele. Thepa ea mechine ea aluminium e kenya letsoho ho litekanyetso tsa polokeho ea koloi. Mohlala, matla a tsitsipano a profil ea aluminium extrusion a tloha ho180-220 MPa, ha matla a tlhahiso a ka fihla90-140 MPa. Ha ho bapisoa, tšepe ea setso hangata e na le matla a thata a455 MPale matla a tlhahiso ea380 MPa. Leha ho le joalo, bokhoni ba aluminium ba ho monya matla nakong ea tšusumetso bo etsa hore e be khetho e sireletsehileng bakeng sa moralo oa koloi. Peresente ea elongation ea aluminium, e tlohang ho10-25%, e lumella deformation e ntle ntle le ho hlōleha, ho matlafatsa polokeho ea koloi ka kakaretso.

Litšenyehelo-Ka katleho

Ha ho nahanoalitšenyehelo tsa tlhahiso, litlaleho tsa aluminium extrusion li fana ka khetho ea tlhōlisano. Le hoja litšenyehelo tsa pele tsa lisebelisoa tsa aluminium li ka 'na tsa e-ba tse phahameng ka lebaka la nts'etsopele ea lefu le liaparo tse khethehileng, melemo ea nako e telele e atisa ho feta litšenyehelo tsena. Ka mohlala, litšenyehelo tsa tlhokomelo tse amanang le likoloi tse sebelisang profiles tsa aluminium li atisa ho theoha ha nako e ntse e ea. Tlhahlobo e tloaelehileng ea litšenyehelo tsa potoloho ea bophelo e senola hore likoloi tsa aluminium ha li hloke ho lokisoa le ho hlokomeloa khafetsa ha li bapisoa le litšepe tsa tsona.

| Mofuta oa Boitsebiso | Lintlha tsa litšenyehelo | Ho bapisoa le Aluminium |

|---|---|---|

| Aluminium | Litšenyehelo tse phahameng tsa lisebelisoa, nts'etsopele ea lefu, liphahlo tse khethehileng | Ka kakaretso e phahame ho feta tšepe ka lebaka la lisebelisoa le theko ea thepa |

| Tšepe | Litšenyehelo tse tlase tsa lisebelisoa, litheko tse potlakileng tsa litempe | E bitsa chelete e ngata ho feta aluminium lits'ebetsong tse ngata |

| Motsoako | E fapana ho latela ts'ebeliso | Katleho ea litšenyehelo e ka ba le tlholisano ho latela ts'ebetso |

Melemo ea Moshoelella

Aluminium extrusion profiles e bapala karolo ea bohlokoa ho ntlafatseng ts'ebetso ka har'a indasteri ea likoloi. Lintho tsa bona tse bobebe ha li ntlafatse ts'ebetso ea mafura feela empa hape li fokotsa haholo mesi nakong ea ts'ebetso ea koloi. Ka ho khetha aluminium, u ka thusa likoloi tsa hau ho fihlela lipehelo le melaoana e thata ea Tikoloho, Sechaba, le Puso (ESG). Mona ke melemo ea bohlokoa ea ts'ebetso ea ho sebelisa profil ea aluminium extrusion:

- Tšebeliso ea Matla: Tlhahiso ea aluminium ke matla a matla, a ka amang mesi. Leha ho le joalo, mofuta o bobebe oa aluminium o thusa ho ntlafatsa ts'ebetso ea mafura, e lebisang ho fokotseng tlhahiso ea ts'ebetso.

- Melemo ea ho Recycling: E 'ngoe ea melemo ea bohlokoa ka ho fetisisa ea aluminium ke ho sebelisoa hape. Ho sebelisa aluminium hape95% matla a fokolangho feta ho hlahisa aluminium e ncha ka thepa e tala. Mokhoa ona o lebisa phokotsong e kholo ea likhase.

- Khetho ea Lintho: Khetho ea aluminium e susumetsa boima ba koloi, tšebeliso ea matla, le phello ea kakaretso ea carbon dioxide (CO2e). Ka ho khetha li-profiles tsa aluminium extrusion, o kenya letsoho molemong oa ts'ebetso e tsitsitseng ea tlhahiso.

- Tšireletso ea Nako e telele ea Phepelo: Ho sebelisa aluminium ho ntlafatsa ho tsebahatsa litšenyehelo le ho tšoarella. Botsitso bona bo bohlokoa kaha indasteri ea likoloi e tobane le litšenyehelo tse feto-fetohang tsa thepa le liphephetso tsa phepelo ea thepa.

Tafole e latelang e akaretsa kamoo profaele ea aluminium extrusion e amang khabone ea tlhahiso ea likoloi:

| Karolo | Tšusumetso ho Carbon Footprint |

|---|---|

| Tšebeliso ea Matla | Tlhahiso ea aluminium ke matla a matla, a amang mesi. |

| Thepa e bobebe | E ntlafatsa ts'ebetso ea mafura, e fokotsa tlhahiso ea ts'ebetso. |

| Melemo ea ho Recycling | Aluminiamo ea ho sebelisoa hape e sebelisa matla a tlase ho 95% ho feta tlhahiso ea mantlha, e lebisang ho theolelo ea likhase. |

| Khetho ea Lintho | E susumetsa boima ba koloi, tšebeliso ea matla, le phello ea CO2e. |

| Tšireletso ea Nako e telele ea Phepelo | E ntlafatsa ho tsebahatsa litšenyehelo le ho tšoarella. |

Ho feta moo, ho fihlela ho75%ea aluminium e sebelisoang liprofaeleng tsa extrusion bakeng sa lits'ebetso tsa likoloi e ka tsoa ho litaba tse nchafalitsoeng ka morao ho bareki. Sekhahla sena se phahameng sa ho sebelisoa hape ha se baballe lisebelisoa feela empa hape se fokotsa tšusumetso ea tikoloho e amanang le ho ntšoa ha thepa e tala.

Ka ho kopanya lintlha tsa aluminium extrusion ho meralo ea hau ea likoloi, u kenya letsoho ka mafolofolo bokamosong bo tsitsitseng. Motsoako oa thepa e bobebe, ts'ebetso ea matla, le bokhoni ba ho e sebelisa hape e beha aluminium e le sesebelisoa se etelletseng pele ha ho batloa tharollo ea likoloi tse tala.

Lisebelisoa tsa Aluminium Extrusion Profiles ho Moralo oa Likoloi

Aluminium extrusion profilesphetha karolo ea bohlokoa moralong oa sejoale-joale oa likoloi, ho ntlafatsa ts'ebetso le botle bo botle. Ho feto-fetoha ha tsona ho u lumella ho li kenya ts'ebetsong lits'ebetsong tse fapaneng, ho tloha ho likarolo tsa sebopeho ho ea ho likarolo tse rarahaneng tsa botle.

Likaroloana tsa Sebopeho

U ka fumana liprofaele tsa aluminium extrusion likarolong tse 'maloa tsa bohlokoa tsa meralo ea likoloi. Litaba tsena li fana ka matla a hlokahalang ha li ntse li fokotsa boima ba 'mele haholo. Lisebelisoa tse tloaelehileng li kenyelletsa:

- Likarolo tsa Chassis: Liprofaele tsena li fana ka botšepehi ba sebopeho, ho netefatsa hore koloi e lula e tiile empa e le bobebe.

- Mehaho ea Kotsi: Li monya matla a matla, li matlafatsa polokeho ea bapalami nakong ea likoluoa .

- Likabelo tsa Battery: Likoloing tsa motlakase, litlaleho tsena li sireletsa likarolo tse hlokolosi, ho netefatsa hore li phela nako e telele le ho tšepahala.

- Liforeimi tsa 'Mele: E bohlokoa bakeng sa ho boloka sebopeho sa koloi ka kakaretso.

- Likarolo tsa Chassis: Likarolo tsa bohlokoa tse tšehetsang boima le botsitso ba koloi.

- Litsamaiso tsa Tsamaiso ea Crash: E bohlokoa bakeng sa polokeho, lits'ebetso tsena li sebelisa lintlha tsa aluminium ho fokotsa likotsi nakong ea likotsi.

Profaele ea aluminium extrusion e ntlafatsa ho senyeha ha likarolo tsa sebopeho sa likoloi. Mohlala, ho sebelisa liprofaele tsena ho ka lebisa ho aPhokotso ea 4.74%.moroalo o phahameng nakong ea litlamorao. Ho feta moo, ba ka eketsa ho monya matla ka7%, ho matlafatsa polokeho ea koloi ka kakaretso.

| Ho fumana | Tlhaloso |

|---|---|

| Peak Mojaro Phokotso | Ho fihlela ho phokotso ea 4.74% ea mojaro o phahameng (Pmax) ka li-discontinuities. |

| Keketseho ea ho Monya Matla | Keketseho ea 7% ea ho monya matla (Ea) e bonoang ka li-discontinuities. |

| Tšebeliso ea Matla a Crush | Keketseho ea 12.69% ea katleho ea matla a silakanya (CFE) e boletsoeng ka li-discontinuities tsa mochini. |

Likarolo tsa Aesthetic

Lifaele tsa aluminium extrusion le tsona li kenya letsoho haholo ho boipiletso bo botle ba likoloi. Melemo ea bona ea moralo e lumella motsoako oa ts'ebetso le mokhoa. Melemo ea bohlokoa e kenyelletsa:

| Molemo | Tlhaloso |

|---|---|

| Karolelano ea matla ho boima ba 'mele | Aluminium e bobebe ho feta tšepe ha e ntse e boloka matla a sebopeho se phahameng, e loketse lisebelisoa tsa likoloi. |

| Ho feto-fetoha ha moralo | Extrusion ea tloaelo e lumella liprofaele tse rarahaneng le tse rarahaneng, tse ntlafatsang ts'ebetso le botle bo botle. |

| Khanyetso ea kutu | Khanyetso ea tlhaho ea aluminium ho kutu e etsa hore e tšoanelehe bakeng sa lisebelisoa tsa likoloi tse pepesehileng libakeng tse fapaneng. |

U ka etsa meralo ea kantle ea koloi le ea ka hare u sebelisa li-profiles tsa aluminium extrusion. Mokhoa ona o kenyelletsa likarolo tsa 'mele, likarolo tsa chassis le likarolo tsa kahare. Mohlala, o ka rala liforeimi tsa dashboard tse lokiselitsoeng le masaka a litulo tse ntlafatsang botle le ts'ebetso.

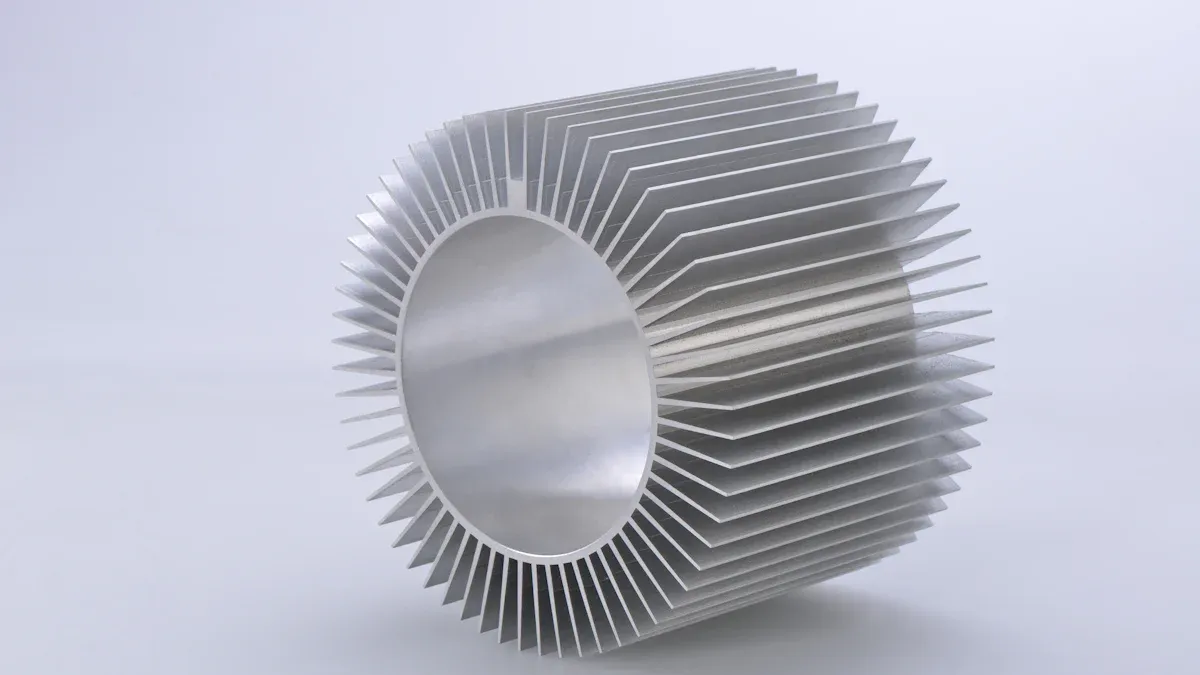

Li-heaters tsa mocheso le li-radiator

Litsamaisong tsa ho futhumatsa likoloi, li-profiles tsa aluminium extrusion li sebetsa hantle haholo. Li entsoe ka mokhoa o ikhethilengtshebetso ya mocheso, ho netefatsa phapanyetsano e nepahetseng ea mocheso. Lintlha tsa bohlokoa li kenyelletsa:

| Sebopeho | Tlhaloso |

|---|---|

| Ts'ebetso ea Mocheso | E etselitsoe ts'ebetso e ikhethang ea mocheso, e netefatsa phapanyetsano e nepahetseng ea mocheso. |

| Ho tšoarella | Tsepamisa maikutlo ho tšoarella bakeng sa tšebeliso ea nako e telele lits'ebetsong tse fapaneng. |

| Moqapi o bobebe | E loketse mefuta e fapaneng ea litlhophiso tsa radiator ka lebaka la thepa e bobebe. |

Li-alloys tsa aluminium, tse kang 6061 le 6063, li tsejoa ka mokhoa o phahameng oa ho futhumatsa mocheso. Thepa ena e bohlokoa bakeng sa taolo e sebetsang ea mocheso lits'ebetsong tsa ho pholisa likoloi. Sebopeho sa bona se bobebe le ho feto-fetoha ha maemo moralong le ho feta ho ntlafatsa ho tšoaneleha ha tsona lits'ebetsong tsena.

Ka ho kopanya lintlha tsa aluminium extrusion ho meralo ea likoloi tsa hau, ha u ntlafatse botšepehi ba sebopeho le botle bo botle feela empa hape u ntlafatsa taolo ea mocheso, ho etsa hore likoloi tsa hau li sebetse hantle le ho hohela.

Lipontšo tsa Likoloi tsa Motlakase Tse Sebelisang Aluminium Extrusion Profiles

Battery Housing Tharollo

U ka ntlafatsa haholo polokeho le katleho ea likoloi tsa motlakase ka ho sebelisaaluminium extrusion profilesbakeng sa matlo a betri. Liprofaele tsena li fana ka tse 'maloamelemo ea bohlokoa:

- Ho tšoarella: Li netefatsa hore lipakete tsa betri li sirelelitsoe hantle khahlanong le litlamorao.

- E bobebe: Sena se kenya letsoho phokotsong e kholo ea boima ba 'mele, ea bohlokoa bakeng sa katleho ea koloi ea motlakase.

- Tumellano ea Taolo: Lintlha tsa aluminium li finyella litekanyetso tsa tšireletso bakeng sa liphahlo tsa betri.

- Kopano e Nolofalitsoeng: Ba thusa kaho e bonolo ea li-module tsa betri.

- Tšireletso ea motlakase ea motlakase: Sena se sireletsa lisebelisoa tsa elektronike hore li se ke tsa sitisoa.

- Monyetla oa Matla: Aluminium e sebetsa hamolemo maemong a ho oa ha ho bapisoa le lisebelisoa tse ling.

Ka ho sebelisa aluminium, u fihlella phokotso ea boima ba ho fihlela ho50%ha e bapisoa le mekotla e tloaelehileng ea libeteri tsa tšepe. Ho boloka sena ka bongata ho ntlafatsa mefuta ea koloi le ho sebetsa hantle ha matla.

Moralo oa Chassis e bobebe

Profaele ea aluminium extrusion e bapala karolo ea bohlokoa ho rala chassis e bobebe bakeng sa likoloi tsa motlakase. Ka ho fetola tšepe ka aluminium, u ka finyella ho fokotsa boima ba 'mele25-30%. Phokotso ena e ntlafatsa ho potlakisa le ho sebetsa hantle ha matla. Botšepehi ba sebopeho sa aluminium bo tiisa hore betri e lula e sirelelitsoe nakong ea likotsi, ho matlafatsa matla a chassis ka kakaretso.

| Molemo | Tlhaloso |

|---|---|

| Botšepehi ba sebopeho | E sireletsa betri nakong ea likotsi, e matlafatsa matla a chassis ka kakaretso. |

| Tsamaiso ea mocheso | E tlosa mocheso o hlahisoang nakong ea ho tjhaja le ho sebetsa, ho bohlokoa bakeng sa polokeho ea betri. |

| Tšireletso e bobebe | E fokotsa boima ba betri, e ntlafatsa bokhoni ba koloi le mefuta e fapaneng. |

| Boikemisetso | Likanale tse kopaneng tsa ho pholisa le lithapo li fokotsa ho rarahana ha moralo le palo ea likarolo. |

| Sistimi ea taolo ea likotsi | E etselitsoe ho holofala ka mokhoa o sa lebelloang tlas'a tšusumetso, e monyang matla le ho sireletsa bapalami. |

Mekhoa ea Tsamaiso ea Mocheso

Tsamaiso e sebetsang ea mocheso ke ea bohlokoa bakeng sa ts'ebetso le nako e telele ea likoloi tsa motlakase. Litlaleho tsa aluminium extrusion li ipabola sebakeng sena ka lebaka la tlhaho ea tsona ea tlhaho ea mocheso. U ka sebelisa li-extrusions tsa aluminium tse tloaelehileng matlong a betri le lipoleiti tse pholileng ho ntlafatsa taolo ea mocheso.

- Ts'ebetso e phahameng ea ho senya mocheso: Sena se ntlafatsa bophelo ba betri le ts'ebetso.

- Tlhaho e bobebe: E tlatsetsa katlehong ea koloi ka kakaretso, haholo-holo nakong ea maemo a tlhokahalo e phahameng.

- Li-tubes tse pholisang tsa serpentine: E entsoe ka aluminium e extruded, tsena li ntlafatsa phallo ea pholiso, li boloka mocheso o loketseng bakeng sa lisele tsa betri.

Ka ho kopanya lintlha tsa aluminium extrusion tsamaisong ea hau ea mocheso, u etsa bonnete ba hore koloi ea hau ea motlakase e sebetsa hantle le ka botšepehi.

Papiso ea Aluminium Extrusion Profiles le Lisebelisoa tsa Setso

Tšepe khahlano le Aluminium

Ha u bapisa tšepe le aluminium, u tla hlokomela phapang e khōlō ea thepa ea mochine le lisebelisoa. Lintlha tse ling tsa bohlokoa tseo u ka li nahanang ke tsena:

- Matla a tšepe: Mebala ea tšepe ho tloha400 MPa ho 500 MPa, ha aluminium e ntse e le teng90 MPa. Sena se bontša hore tšepe e khona ho mamella tsitsipano e kholoanyane.

- Matla a Khatellang: Tšepe e feta aluminium, e jara meroalo e phahameng ntle le ho senyeha ho hoholo.

- Kotulo Matla: Matla a tlhahiso ea tšepe a haufi250 MPa, ha e bapisoa le ea aluminium40 MPa, ho bonts'a molemo oa matla a tšepe.

Ha aluminium e ntse e lebobebe, matla a phahameng a tšepe a lumella meralo e mosesaane, e ntlafatsang bokhoni ba ho jara moroalo. Leha ho le joalo, tlhaho ea aluminium e bobebe e etsa hore e tšoanelehe bakeng sa lits'ebetso moo ho fokotsa boima ba 'mele ho leng bohlokoa.

Lisebelisoa tse Kopantsoeng

Lisebelisoa tse kopaneng li fana ka melemo e ikhethang lits'ebetsong tsa likoloi. Ba kopanya lisebelisoa tse fapaneng ho finyella ts'ebetso e phahameng. Mona ke kamoo li bapisoang le li-profiles tsa aluminium extrusion:

- Boima ba 'mele: Lisebelisoa li ka ba bobebe ho feta aluminium, ho itšetlehile ka lisebelisoa tse khethehileng tse sebelisoang.

- Matla: Likarolo tse ling li bonts'a likarolelano tse phahameng tsa matla ho isa ho boima, e leng se etsang hore li qothisane lehlokoa le aluminium lits'ebetsong tse itseng.

- Litšenyehelo: Ka kakaretso, li-composite li ka ba theko e boima ho feta aluminium ka lebaka la mekhoa e rarahaneng ea tlhahiso.

Aluminium extrusion profileslula e le khetho e tsebahalang ka lebaka la ho leka-lekana ha litšenyehelo, boima ba 'mele le matla, e leng se etsang hore e be tse loketseng lits'ebetso tse fapaneng tsa likoloi.

Metrics ea Ts'ebetso

Ha ho lekoa metrics ea ts'ebetso, profaele ea aluminium extrusion e sebetsa hantle libakeng tse 'maloa:

- Crash Test Ratings: Lisebelisoa tsa aluminium, haholo-holo tse ka har'a5xxx letoto, li tsejoa ka matla a tsona a phahameng le ho fokotseha ha tsona. Motsoako ona o ntlafatsa ts'ebetso ea crash.

- Ho boloka Boima: Profiles Aluminium ka finyella ho boloka boima ba ho fihlela ho25%ha e bapisoa le meaho ea tšepe ea setso. Phokotso ena e kenya letsoho ho ntlafatseng ts'ebetso ea mafura le ho fokotsa mesi.

- Monyetla oa Matla: Aluminium e ka monya matla ka katleho nakong ea likotsi, ea ntlafatsa polokeho ea bapalami.

Mekhoa le Liqholotso tsa Kamoso bakeng sa Aluminium Extrusion Profiles

Tsoelo-pele ho Theknoloji ea Extrusion

U ka lebella tsoelo-pele e kholotheknoloji ea aluminium extrusionseo se tla bopa indasteri ea likoloi. Lintlha tse ling tsa bohlokoa tseo u ka li shebellang ke tsena:

- Ho fokotsa tlhahiso ea carbon: Baetsi ba tsepamisitse maikutlo ho fokotsa ho tsoa ha carbon ho pholletsa le phallo ea boleng ba tlhahiso ea aluminium. Phetoho ena e khothaletsa botsitso le ho ikamahanya le lipheo tsa lefats'e tsa tikoloho.

- Matla a Phahameng a Alloys: Nts'etsopele ea matla a phahameng a 6000 letoto la li-alloys tsa aluminium e ntlafatsa ho tšoarella lits'ebetsong tsa likoloi. Li-alloys tsena li fana ka ts'ebetso e ntle ha li ntse li boloka litšobotsi tse bobebe.

- Matla a Extrusion a Micro: Ho kenyelletsoa ha micro-extrusion ho lumella ho hlahisa li-profiles tse fokolang haholo. Bokhoni bona bo bohlokoa bakeng sa ho theha likarolo tsa likoloi tsa motlakase, moo ho bolokang sebaka le boima ba 'mele ho leng bohlokoa.

Mathata a Tlhokahalo ea Limmaraka le Ketane ea Thepa

The likoloi aluminium extruded profiles maraka tobane le mathata ka lebaka laho feto-fetoha ha litheko tsa thepa e tala. U ka hlokomela hore litšenyehelo tsa li-ingots le li-billet tsa aluminium li susumetsoa ke litšitiso tsa phepelo ea lefats'e, litheko tsa matla le tsitsipano ea tikoloho. Lintlha tsena li thatafatsa bokhoni ba hau ba ho laola litšenyehelo tsa tlhahiso ka katleho. Ho feta moo, khaello ea basebetsi le mathata a lipalangoang a sitisa li-extruder tsa aluminium ho fihlela litlhoko tsa ho fana ka nako ka nako. Ka lebaka leo, u ka ba le tieho kapa litšenyehelo tse eketsehileng tsa ho fumana liprofaele tsa aluminium bakeng sa merero ea hau ea likoloi.

Mehopolo ea Taolo le ea Tikoloho

Melao ea tikolohoe bapala karolo ea bohlokoa ho amoheloeng ha lintlha tsa aluminium extrusion indastering ea likoloi. Litšusumetso tse ling tsa bohlokoa ke tsena:

- Melawana e kgothalletsa tshebediso ya disebediswa tse bobebe ho fihlella maemo a tlhahiso.

- Maemo a matla a moruo a mafura le litaelo tsa motlakase li khothaletsa ho amoheloa ha profil ea aluminium.

- Melao e mabapi le ho sebelisoa hape le melao-motheo ea moruo e chitja e tsamaisa boqapi mekhoeng ea ho etsa aluminium hape.

- Phetoho e lebisang ho likoloi tsa motlakase (EVs) e potlakisoa ke likhatello tsa taolo, e leng ho eketsa tlhokahalo ea likarolo tsa aluminium.

Ka ho lula u tseba ka mekhoa le liphephetso tsena, u ka khona ho bona boemo bo ntseng bo tsoela pele ba profil ea aluminium extrusion lekaleng la likoloi.

Ho kopanngoa ha aluminium extrusion profiles ho fetola haholo indasteri ea likoloi. U rua molemo ho likoloi tse bobebe tse matlafatsang ts'ebetso ea mafura le ho fokotsa mesi. Liprofaele tsena li boetse li tšehetsa meralo e ncha, e u lumellang ho theha likoloi tse fihlelang litekanyetso tsa sejoale-joale tsa ts'ebetso. Ha indasteri e ntse e tsoela pele, ho amohela lintlha tsa aluminium extrusion ho tla ba bohlokoa bakeng sa ho lula u le tlholisano le boikarabello ba tikoloho.

LBH

Liprofaele tsa aluminium extrusion ke life?

Aluminium extrusion profileske libōpeho tse entsoeng ka ho qobella aluminiamo ka lesela. Ts'ebetso ena e lumella bahlahisi ho hlahisa libopeho tse rarahaneng tse bobebe, tse matla, le tse fapaneng bakeng sa lits'ebetso tse fapaneng tsa likoloi.

Liprofaele tsa aluminium extrusion li ntlafatsa polokeho ea koloi joang?

Liprofaele tsena li monya matla a matla nakong ea ho thulana, ho matlafatsa polokeho ea bapalami. Moralo oa bona o lumella deformation e ntle ntle le ho hloleha, e thusang ho ntlafatsa ho senyeha ha likoloi.

Na liprofaele tsa aluminium extrusion li na le litšenyehelo?

E, le hoja litšenyehelo tsa ho qala tsa lisebelisoa li ka 'na tsa e-ba holimo, litlaleho tsa aluminium hangata li lebisa ho theola litšenyehelo tsa tlhokomelo ha nako e ntse e feta. Ho tšoarella ha tsona le ho ba bobebe ho ka etsa hore ho bolokoe haholo ts'ebetsong ea mafura.

Liprofaele tsa aluminium extrusion li phetha karolo efe likoloing tsa motlakase?

Likoloing tsa motlakase, li-profiles tsa aluminium extrusion li bohlokoa bakeng sa matlo a betri, meralo e bobebe ea chassis, le sistimi ea taolo ea mocheso. Li ntlafatsa polokeho, katleho, le ts'ebetso ea koloi ka kakaretso.

Liprofaele tsa aluminium extrusion li tšoarella hakae?

Aluminium extrusion profiles kee tsitsitseng haholo. Li ka ba le lintho tse ka bang 75% tse sebelisitsoeng hape, 'me aluminium ea ho sebelisa hape e sebelisa matla a tlase ho 95% ho feta ho hlahisa aluminium e ncha, e leng ho fokotsang tšusumetso ea tikoloho haholo.