Ho etsa ente e nepahetseng ho phetha karolo ea bohlokoa ho ntlafatseng moralo oa likoloi. E ntlafatsa haholo ts'ebetso le ts'ebetso ka ho theha likarolo tse bobebe, joalo ka profil ea aluminium extrusion, e kenyang letsoho ho sebetsa hantle ha mafura. Ho phaella moo, tlhahiso ealikarolo tsa likoloi tsa polasetikika ts'ebetso ena e ncha e fokotsa litšila tsa thepa, e fana ka tharollo e theko e tlaase e tsoelang bahlahisi le tikoloho molemo. Ho feta moo, theknoloji e ka sebelisoa ho theha likarolo tse khethehileng tse kang li-drain tse nang le li-drain tse nang le lithapo tsa metsi le li-tubes tsa koporo tse pholileng tsa metsi, tse bontšang ho feto-fetoha ha eona lits'ebetsong tse fapaneng.

Lintlha tsa bohlokoa

- Precision ente molding e ntlafatsa moralo oa likoloi ka ho thehalikarolo tse bobebe, ho ntlafatsa ts'ebetso ea mafura, le ho fokotsa litšila tsa thepa.

- Ts'ebetso ena e fana ka phetoho e ikhethang ea moralo, e lumellang hore ho be le libopeho tse rarahaneng le ho kopanngoa ha lisebelisoa tse fapaneng karolong e le 'ngoe.

- Ho amohela mokhoa o nepahetseng oa ho etsa ente ho lebisa polokong e kholo ea litšenyehelo ka ho fokotsa litšila le ho ntlafatsa lits'ebetso tsa tlhahiso, ho etsa hore e be ea bohlokoa bakeng sa tlhahiso ea tlholisano.

Melemo ea Precision Ente Molding

Ho etsa ente e nepahetseng ho fana ka melemo e mengata e ntlafatsang haholo moralo oa likoloi. Ka ho sebelisa ts'ebetso ena e ncha, o ka fihlela lintlafatso tse makatsang molemong oa ho feto-fetoha le maemo, ho sebetsa hantle ha thepa, le ho baballa litšenyehelo.

Moqapi oa Fetola

E 'ngoe ea melemo e hlahelletseng ea ho bopa ente e nepahetseng ke e ikhethangho feto-fetoha ha moralo. Ts'ebetso ena e u lumella ho theha li-geometri tse rarahaneng le tse rarahaneng tseo mekhoa e meng ea tlhahiso e thatafallang ho e fihlela. Mona ke lintlha tse ling tsa bohlokoa tsa ho feto-fetoha ha moralo:

- Multi-shot ho bōpa le overmolding ho u nolofalletsa ho kopanya lisebelisoa tse thata le tse bonolo ka karolo e le 'ngoe. Sena se ntlafatsa ts'ebetso le boiketlo ha se ntse se fokotsa mehato ea kopano.

- Bokhoni ba ho hlahisa libopeho tse rarahaneng, tse kang li-undercuts le marako a tšesaane, li bula lefats'e la menyetla ea ho qapa likarolo tsa likoloi.

- Mekhoa e tsoetseng pele ea ho bōpa e tšehetsa ho kopanngoa ha lisebelisoa tse fapaneng, ho lumella meralo e ncha e finyellang litlhoko tse khethehileng tsa tshebetso.

Ka ho bopa ka mokhoa o nepahetseng oa ente, o ka sutumelletsa meeli ea moralo oa likoloi, oa theha likarolo tse sa sebetseng feela empa hape li khahleha ka bokhabane.

Tšebeliso e Ntle ea Lintho

Katleho ea lintho tse bonahalangke monyetla o mong oa bohlokoa oa ho bopa ente e nepahetseng. Ts'ebetso ena e fokotsa litšila mme e eketsa ts'ebeliso ea lisebelisoa tse tala, tse bohlokoa 'marakeng oa kajeno o hlokomelang tikoloho. Nahana ka lintlha tse latelang:

- Likhamphani li na le phokotso ea 25-40% ea litšila le bofokoli ha li sebelisa sebopeho se nepahetseng. Sena se bolela hore o ka hlahisa likarolo tse ngata ka thepa e fokolang.

- Ka karolelano, 98% ea thepa e tala e rekiloeng e sebelisoa lihlahisoa tsa ho qetela ka mokhoa ona. Boemo bona bo phahameng ba ho sebetsa hantle bo fetolela ho boloka litšenyehelo tse kholo.

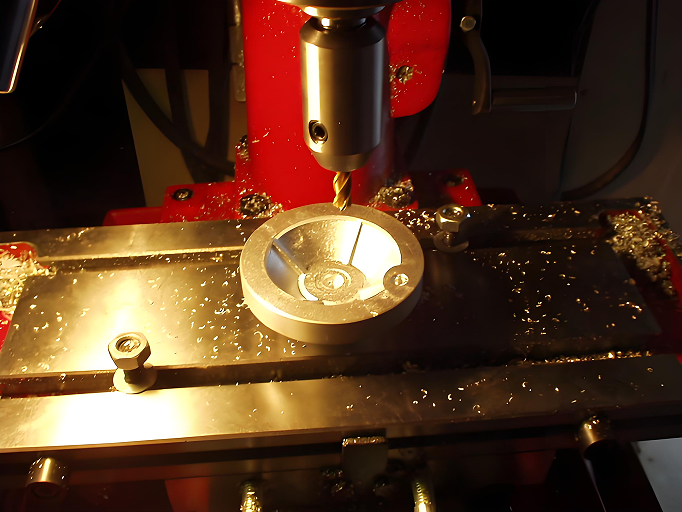

- Mokhoa ona o kenyelletsa ho qhibilihisa resin ea polasetiki, ho e kenya ka har'a hlobo e entsoeng ka mochini o nepahetseng, le ho e pholisa ho etsa likarolo tse rarahaneng tsa likoloi. Sena se netefatsa hore o fihlella lintlha tse phahameng le ho nepahala, tse bohlokoa bakeng sa likarolo tse rarahaneng joalo ka li-dashboard le liphanele tsa mamati.

Ka ho sebelisa mokhoa o nepahetseng oa ente, ha o ntlafatse boleng ba likarolo tsa koloi ea hau feela empa hape o kenya letsoho boitekong ba ts'ebetso ka ho fokotsa litšila tsa thepa.

Litšenyehelo-Ka katleho

Ho boloka litšenyehelo ke taba ea bohlokoa bakeng sa moetsi ofe kapa ofe oa likoloi. Ho bopa ente e nepahetseng ho ipabola sebakeng sena ka ho fokotsa litšila le ho ntlafatsa mekhoa ea tlhahiso. Mokhoa ona ke ona:

- Tlhahiso e phahameng e theola litšenyehelo tsa yuniti ka ho jala litšenyehelo tsa ho seta ka likarolo tse ngata. Sena se etsa hore e be chelete e ngata bakeng sa lihlopha tse kholo.

- Litheknoloji tse tsoetseng pele joalo ka CAD li ntlafatsa ts'ebetso ea moralo, ho ntlafatsa ts'ebeliso ea thepa le ho fokotsa litšenyehelo tsa tlhahiso ka kakaretso.

- Mokhoa ona o lumella tšebeliso e nepahetseng ea thepa, e lebisang ho bolokeheng ha thepa ea bohlokoa.

Ho feta moo, melemo ea nako e telele ea ho sebelisa ente ka mokhoa o nepahetseng e kenyelletsa ts'ebetso e phahameng le lebelo, liphetho tsa boleng bo holimo, le moruo oa sekala. Lintlha tsena ka kopanelo li kenya letsoho tšebetsong ea tlhahiso e baballang chelete e ngata, ho netefatsa hore u lula u le tlholisano indastering ea likoloi.

Ka ho amohela sebopeho sa ente e nepahetseng, o ka fihlela boemo bo leka-lekaneng, bo sebetsang hantle, le ho boloka litšenyehelo, oa e etsa sesebelisoa sa bohlokoahali moralong oa sejoale-joale oa likoloi.

Likopo ho Likaroloana tsa Likoloi

Precision ente ea ho bopa e bapala karolo ea bohlokoa tlhahisong ea likarolo tse fapaneng tsa likoloi. Ts'ebetso ena e ntlafatsa ts'ebetso, ho tšoarella, le boipiletso bo botle ba likarolo libakeng tse fapaneng tsa moralo oa koloi. Ha re hlahlobeng hore na ho bopa ente e nepahetseng ho sebetsa joang likarolong tsa enjine, likarolo tsa kahare le liphanele tsa kantle.

Likarolo tsa Enjene

Likarolo tsa enjene li rua molemo haholo ho bopeng ente e nepahetseng. Mokhoa ona o u lumella ho hlahisa likarolo tse bobebe empa tse tšoarellang, tse bohlokoa bakeng sa ho ntlafatsa ts'ebetso ea koloi le ho sebetsa hantle ha mafura. Likarolo tsa enjene tse hlahisoang hangata li kenyelletsa:

- Mefuta e mengata ea ho kenya moea

- Li-valve li koahela

- Mehaho ea li-sensor

- Lihokelo tsa motlakase

Ho sebelisa lisebelisoa tse kang polyamide (PA) le polyphenylene sulfide (PPS) ho netefatsa hore likarolo tsena li mamella mocheso o phahameng le maemo a thata a ho sebetsa. Melemo ea ho sebelisa polasetiki bakeng sa likarolo tsa enjene e kenyelletsa:

- Phokotso ea Boima: Likarolo tse bobebe li ntlafatsa ts'ebetso ea koloi ka kakaretso.

- Ho tšoarella: Ho bopa ka mokhoa o nepahetseng oa ente ho matlafatsa matla le ho tšepahala ha likarolo, ho etsa hore li nke sebaka se loketseng bakeng sa likarolo tsa tšepe tsa setso.

| Molemo | Tlhaloso |

|---|---|

| Lisebelisoa tse sebetsang hantle | E sebelisa thermoplastics e mamellang tikoloho e thata, e matlafatsang matla le ho ts'epahala. |

| Meetso e rarahaneng | E lumella ho theha likarolo tse rarahaneng tse nang le mamello e thata, ho netefatsa boleng bo tsitsitseng. |

| Ho nkela sebaka sa likarolo tsa tšepe | E khona ho hlahisa likarolo tse ka nkang sebaka sa tšepe sebaka, tse tlatsetsang ho tšoarella ka kakaretso. |

Likaroloana tsa ka Hare

Precision ente ea ho bopa e boetse e fetola tlhahiso ea likarolo tsa koloi tse ka hare. Ts'ebetso ena e lumella ho theoa ha lijeometri tse rarahaneng le meralo e kopaneng e ntlafatsang ts'ebetso le botle bo botle. Likarolo tsa bohlokoa tsa kahare tse hlahisoang ka mokhoa ona li kenyelletsa:

- Li-dashboards

- Liphanele tsa mamati

- Li-clips le li-fasteners

Melemo ea ho etsa ente bakeng sa likarolo tsena ke ea bohlokoa:

| Mofuta oa Karolo | Melemo ea ho Bopa ka Ente |

|---|---|

| Li-dashboards | Libopeho tse rarahaneng, nako e telele, boipiletso bo botle |

| Liphanele tsa mamati | Ho pheta-pheta holimo, matla |

| Li-clips le li-Fasteners | Ho nepahala, ho tsitsisa tlhahisong |

Ho feta moo, ho etsa ente ka mokhoa o nepahetseng ho u thusa ho fihlela liphetho tse boreleli le mebala e ikhethileng e lumellanang le moralo oa koloi. Bokhoni bona bo ntlafatsa ponahalo ea likarolo tse kang li-trim tse tloaelehileng le likonopo tsa lisebelisoa, ho etsa hore li se ke tsa sebetsa feela empa hape li khahle.

Liphanele tse ka ntle

Ha ho tluoa ho liphanele tsa kantle, ho bopa ente e nepahetseng ho fana ka melemo e makatsang. Ts'ebetso ena e lumella ho hlahisa likarolo tse bobebe tse ntlafatsang bokhoni ba aerodynamic le boipiletso ba pono. Melemo ea bohlokoa e kenyelletsa:

- Ho nepahala ho phahameng ho hlahiseng libopeho tse rarahaneng, tse hlokahalang bakeng sa likarolo tse rarahaneng tsa koloi.

- Bokhoni ba ho theha liphanele tsa kantle tse bobebe tse ntlafatsang ts'ebetso ea koloi ka kakaretso.

- Lintlafatso tsa botle ka likhakanyo tse boreleli le lintlha tse rarahaneng.

Ho feto-fetoha ha ente ho tšehetsa ho etsoa ha likaroloana tse finyellang litebello tse sebetsang le tse ntle. Sena se tiisa hore liphanele tsa kantle ha li sebetse hantle feela empa hape li kenya letsoho moetsong oa koloi ka kakaretso.

Lithuto Tse Katleho tsa Phethahatso e Atlehileng

Ningbo Tiehou Auto Parts Co., Ltd. Innovations

Ningbo Tiehou Auto Parts Co., Ltd. e etsa mohlala oa boqapi hoho bopa ka ente e nepahetsengka hare ho lefapha la likoloi. E thehiloe ka 2018, k'hamphani ena e na le lilemo tse fetang 20 tsa boiphihlelo tšimong. Boitlamo ba bona ba ho rala le ho hlahisa bokhabane bo lebisitse ho nts'etsopele ea likarolo tsa boleng bo holimo bakeng sa lisebelisoa tse fapaneng tsa likoloi.

Tsepamiso ea bona ea ho tšoarella le litharollo tse shebaneng le bareki e bakile tsoelo-pele e kholo. Ka mohlala, ba kopane ka katlehomekhoa e mengata ea ho bopaho hlahisa likarolo tse rarahaneng tse kopanyang lisebelisoa tse fapaneng. Tlhahiso ena ha e ntlafatse ts'ebetso feela empa hape e fokotsa nako ea kopano, e leng ho etsang hore mokhoa oa ho etsa tlhahiso o atlehe haholoanyane.

Aluminium Extrusion Profiles in Action

Aluminium extrusion profiles e bapala karolo ea bohlokoa ho fokotsa boima ba koloi ha e ntse e boloka matla. Liprofaele tsena li na le likarohano tse phahameng tsa boima ba 'mele, e leng se etsang hore e be tse loketseng likarolo tsa bohlokoa tsa koloi. Melemo ea bohlokoa ke ena:

- Ho fetola sebopeho sa koloi-in-white (BIW) ho tloha tšepeng ho ea aluminium ho ka lebisa phokotsong ea boima ba hoo e ka bang 40% likarolong tse fetotsoeng.

- Thepa e ikhethang ea aluminium, joalo ka conductivity ea mocheso le matla, e ntlafatsa ts'ebeliso ea eona likarolong tse fapaneng tsa koloi.

- Likarolo tse bobebe joalo ka maballo a maholo le likarolo tsa foreimi li thusa ho ntlafatsa ts'ebetso ea mafura le ts'ebetso ea koloi ka kakaretso.

Ka ho sebelisa li-profiles tsa aluminium extrusion, bahlahisi ba ka fumana chelete e ngata ea ho boloka boima ba 'mele, e leng ea bohlokoa bakeng sa moralo oa morao-rao oa likoloi.

Mekhoa ea Bokamoso ho Tlhahiso ea Likoloi

Ha indasteri ea likoloi e ntse e tsoela pele, ho etsa ente e nepahetseng e ntse e tsoela pele ho bapala karolo ea bohlokoa ho bopeng mekhoa ea nakong e tlang ea tlhahiso. U ka lebella tsoelo-pele e kholo ea thepa le ho kopanngoa ha mahlale a morao-rao ho ntlafatsa katleho ea tlhahiso le botsitso.

Tsoelo-pele ho Thepa

Lefapha la likoloi le bona keketseho ea lisebelisoa tse ncha tse ntlafatsang ts'ebetso le ho fokotsa tšusumetso ea tikoloho. Lintlha tse ling tsa bohlokoa ke tsena:

- Likarolo tsa Hybrid: Tsena li kopanya polasetiki le tšepe, li matlafatsa matla ha li ntse li fokotsa boima ba 'mele.

- Lisebelisoa tsa Carbon Fiber: Li fana ka tharollo e bobebe e ntlafatsang ts'ebetso ea mafura le ho fokotsa mesi.

- Litšepe tse Tsoetseng Pele tsa Matla a Phahameng (AHSS): Lisebelisoa tsena li fana ka matla a phahameng, ho lumella ho fokotsa boima ba 'mele ntle le ho etsa sehlabelo.

- Plastiki e thehiloeng ho Bio-based le Recycled: Mekhoa ena e meng e bolokang tikoloho e thusa ho fokotsa litšila le litšenyehelo tsa tlhahiso.

Mmaraka oa li-thermoplastics tse matlafatsang fiber tse tsoelang pele ho nahanoa hore o tla hola haholo, o bonts'a tlhokahalo e matla ea lisebelisoa tse bobebe tse fihlelang melaoana e thata ea tikoloho.

Khokahano le Mahlale a Mang

Ho kopanngoa ha mahlale a tsoetseng pele ho fetola mokhoa o nepahetseng oa ente. U ka lebella ho bona:

- Boiketsetso: Keketseho ea othomathike e tsamaisang tlhahiso, e ntlafatsa ho nepahala le ho fokotsa litšenyehelo tsa basebetsi.

- Artificial Intelligence (AI): AI e ntlafatsa mekhoa ea tlhahiso, e ntlafatsa boleng le ho fokotsa litšila. E sebelisa data ea sensor ea maqhubu a holimo bakeng sa ho bolela esale pele sekoli le taolo ea ts'ebetso.

- Indasteri 4.0 Melao-motheo: Melao-motheo ena e ntlafatsa lits'ebetso tsa tlhahiso, ho netefatsa hore o fihlella ka nepo moralong oa likoloi.

| Thekenoloji | Tšusumetso |

|---|---|

| Boiketsetso | E tsamaisa tlhahiso, e ntlafatsa ho nepahala le ho fokotsa litšenyehelo tsa basebetsi. |

| AI | E fetola sebopeho sa ente e nepahetseng, e ntlafatsa ts'ebetso le boleng. |

| Indasteri 4.0 | E sebelisa mahlale a bohlale ho ntlafatsa lits'ebetso tsa tlhahiso ho moralo oa likoloi. |

Ka ho amohela lintlafatso tsena, o ka ntlafatsa ts'ebetso le botsitso ba tlhahiso ea likoloi, oa beha meralo ea hau molemong oa katleho ea nako e tlang.

Ho etsa ente e nepahetseng ho bohlokoa bakeng sa moralo oa sejoale-joale oa likoloi. E o nolofalletsa ho thehalikarolo tse bobebe, joalo ka profil ea aluminium extrusion, e ntlafatsang ts'ebetso ea koloi. Ts'ebetso ena e boetse e ts'ehetsa ts'ebetso ka ho ntlafatsa ts'ebeliso ea thepa le ho fokotsa tlhahiso ea khabone. Ka ho latela litataiso tse qaqileng tsa moralo, o ka netefatsa boleng le katleho ea likarolo tse bōpiloeng, ho thibela ho hloleha ha tlhahiso le ho boloka botšepehi ba sebopeho.

| Molemo | Tlhaloso |

|---|---|

| Moshoelella | Mahlale a morao-rao a ho etsa ente a rarolla mathata a tikoloho ka thepa e tšoarellang le lits'ebetso tse sebetsang hantle. |

| Litsila tse Fokotsoeng | Ho etsa ente ho fokotsa litšila, ho sebelisa feela palo ea polasetiki e hlokahalang bakeng sa sehlahisoa sa ho qetela. |

| Matla a Matla | Mechini ea sejoale-joale e etselitsoe ho baballa matla, e fokotsang litšenyehelo tsa ts'ebetso haholo. |

LBH

Precision ente molding ke eng?

Precision ente molding ke ts'ebetso ea tlhahiso e bakang ho rarahanalikarolo tsa polasetikika nepo e phahameng le tshenyo e nyane.

Ho etsa ente e nepahetseng ho ka ntlafatsa ts'ebetso ea mafura joang?

Ka ho hlahisa likarolo tse bobebe, ho etsa ente e nepahetseng ho fokotsa boima ba koloi, e lebisang ho ntlafatseng ts'ebetso ea mafura le ts'ebetso.

Ke lisebelisoa life tse atisang ho sebelisoa ha ho etsoa ente e nepahetseng bakeng sa likarolo tsa koloi?

Lisebelisoa tse tloaelehileng li kenyelletsa polyamide (PA), polyphenylene sulfide (PPS), le mefuta e fapaneng ea thermoplastics e fanang ka nako e telele le ho hanyetsa mocheso.